About Seymour

Seymour is an inexpensive, open source, portable extensional rheometer that arose from the desire to study pitcher plant fluids in situ in Brunei Darussalam. It was named Seymour after the owner of a carnivorous plant in the movie ‘Little Shop of Horrors’. The device can be used for routine testing as well as field work. It offers the following advantages:

- it is lightweight, robust, easy to assemble and has few moving parts;

- it is constructed mainly from standard parts, which can be replaced readily, and is therefore relatively inexpensive;

- it employs small sample volumes (< 10 µL), which fits the increasing demand for the miniaturisation of rheometric techniques owing to the limited availability or high cost of samples;

- it is easy to operate. Data can be analysed directly or remotely.

- it is suitable for testing at temperatures other than ambient as it fits readily into a controlled environment chamber: many studies of extensional rheology to date have been limited to ambient conditions.

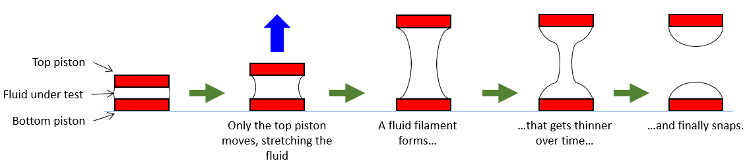

Traditional capillary break-up extensional rheometers, such as the Haake CaBERTM, operate by stretching a fluid sample between two pistons that move away from each other rapidly. Once stretched, the fluid forms a thin, cylindrical, filament that then decreases in diameter under the action of surface tension, eventually breaking. Depending on the nature of the fluid, filament breakup may take anywhere between milliseconds to seconds! Measuring the diameter of the thinnest part of the fluid filament as a function of time (typically with a laser micrometer) yields a signifcant amount of information concerning the nature of the fluid, which can then be put to good use by engineers and scientists. The mechanism used to move the rheometer pistons away from each other is a piece of precision engineering - the objective is to keep the midpoint of the fluid filament in the same location. This makes subsequent diameter measurement easy since the thinnest part is always in the same place; it does also have consequences for size, complexity, cost and portability! The diagram below illustrates this concept.

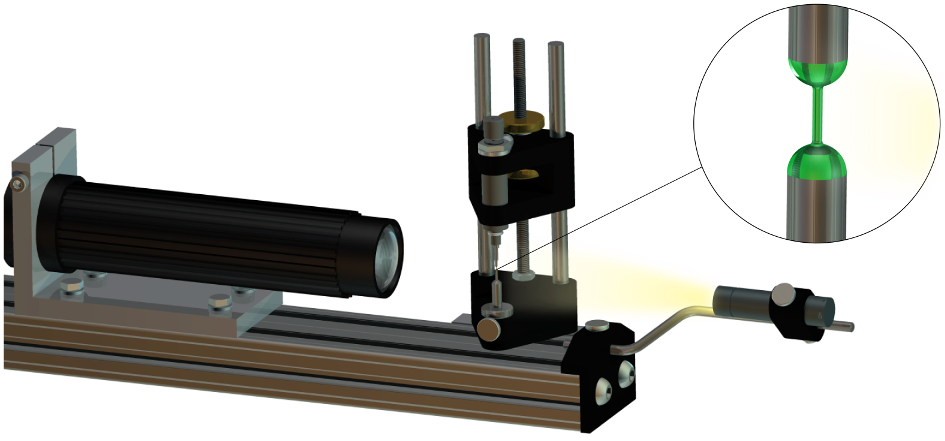

Seymour operates in a simpler manner - only one piston is mobile and is operated by a simple solenoid. A fluid filament can still be formed, but the midpoint of the fluid at the beginning of the test and at the end of the test are in different locations! Everything is a compromise - simplifying the mechanics of Seymour to make it inexpensive, light and portable, results in a more challenging image processing and measurement problem. This is solved by taking advantage of cheap computing power and by using the new generation of compact, robust, solid-state high speed cameras. The time resolution of these cameras is still significantly lower than laser micrometers, but they are suitable for a range of medium to high viscosity Newtonian liquids (typically 500 mPa s and above) and viscoelastic liquids. A diagram of Seymour's operation is shown below.

Seymour weighs less than 1 kg and the solenoid uses a 9V battery for its power. The most significant cost is the solid-state high speed camera (between £350 and £1000, depending on make, model and frame-rate [July 2016 prices]) and high magnification lens (we use a now-obsolete Leica Bausch & Lomb MonoZoom 7 C-mount video microscope lens with a magnification range between 1.5x and 10.5x - typical eBay prices vary between £210 - £500). Building Seymour from the engineering drawings available for download on this website does require access to a mechanical workshop and expertise in turning and milling. We will be working on a set of 3D printable designs to minimise fabrication effort in the future. The image analysis code available for download on this website runs in Ubuntu Linux and has been written for use with OpenCV v2.4 for use with a 500 frame-per-second Ximea camera using and the XimeaAPI. Compiling and modification of this code to work with other cameras will be possible, but will require some experise in C++.